Dry air/gases for analytical instruments

From NMR Wiki

Stream of dry gases (air or nitrogen) are used in the practice of NMR spectroscopy to regulate sample temperature.

Typically gas is cooled to some temperature that is lower then the desired sample temperature. Cooled gas is then passed through electric heater where it reaches the target temperature and then comes in contact with the sample.

Contents |

Dew point sensing

Dew point of gas is an important parameter to consider. Dew point should be 20oC below the lowest temperature anywhere in the path of the gas stream [1].

| model | range | precision | notes |

| GE DewPro MMY30 | -130oF to 500F (-90 to 10oC) | 2oC |

|

Dry air/nitrogen solutions

Boil-off nitrogen

Boil-off nitrogen. Very dry, dew point probably around -200C if (i) the evaporator chamber in the source tank is free of ice (ii) delivery tubing made of material that does not allow diffusion of water across the walls. Best results are achieved when using big industrial-size outdoor tanks. Portable tanks (~200L) can once in a while come with a wet evaporation chamber if tanks are left open while they are still cold by whoever handled the tank before. Frost will blow out and may even be visible as white particles flying along. The evaporation chamber can even take some hydraulic fluid if filling is done incorrectly.

Desiccant dryers

Desiccant dryers work by absorbing water vapor with a desiccant material, e.g. molecular sieves. Desiccant needs to be regenerated, which usually requires heat. There is some confusion in terminology. For example Hankison makes units that they call "heatless desiccant dryers", which are actually based on PSA technology.

Dryers based on molecular sieves can achieve dewpoint of -86oC, routinely -73oC.

Pressure Swing Adsorption dryers

PSA dryers (pressure-swing adsorption). Models with dew point -73oC are available (see Balston UDA300).

These work by using difference in kinetic rate of adsorption of gases by some surface, e.g. activated alumina or carbon (alumina is used in dryers). Typically there are two towers - one in adsorption cycle, another in desorption. Separation happens during the adsorption cycle. Desorption happens spontaneously when the pressure is reduced during the desorption cycle.

As a side-effect PSA dryers generate gas with a swinging concentration of oxygen, which can in turn swing lock level as well. Large ballast tanks can even out those oxygen level oscillations. See example of setup with ballast tanks here. Alumina powder is abrasive, so it's a good idea to install 0.1 micron filter after the dryer. Some commercial dryers have that filter included, others don't.

Membrane dryers

The membrane in these dryers has pore size less then mean free path of the molecule. In this regime (Knudsen diffusion) flow is proportional to inverse of square root of the molecular mass. So smaller molecules like hydrogen and water leak through the walls of the membrane faster, larger molecules keep going along the tube made of the membrane material. These dryers are probably the most robust, as the required maintenance is minimal.

Refrigeration dryers

Refrigeration dryers condense water vapor by cooling air below the dew point. Commercial units achieve dew points just around 0oC.

Manufacturers

Hankison, Inc. Tel: 724-745-1555 (USA) 52-444-8 15 79 74 (Mexico & South America) 49-2841-819 0 (Europe) +86 021-2208 5840 (Asia)

Donaldson has split off their air drying unit into a separate company in 2008. Their old contact info is:

Donaldson 866-256-7708 (USA) compressedair@donaldson.com

Tubing materials

When delivering dry gas to point of use, appropriate tubing material should be used. Plastics contain molecular size pores that pass small molecules such as water.

Copper tubing works best. What exact types of plastic work still needs to be sorted out.

Connecting tubes

It is important to use appropriate tubing for delivery of ultra-dry gas.

Copper is best, thick wall high density polyethylene is second best. Polyuretane is not recommended.

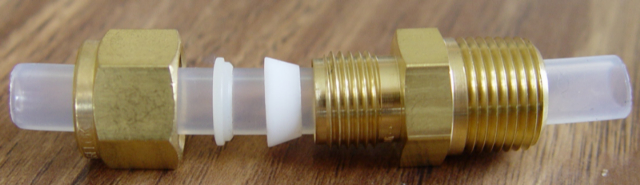

Swagelok

Swagelok compression fittings should be assembled as follows:

Nylon ferrules are best for plasting tubings, since metal ferrules will cut plastic on compression.

Tightening:

- screw on the nut fingertight,

- for tubes smaller then 1/4 inch make 1 1/4 full turns with wrench

- for 1/8,1/16 and 3/16 tubings make 3/4 turns

References

- Instruction manual for FTS XR401 Air-Jet crystal cooler