ESR900 continuous flow cryostat

From NMR Wiki

Product page: ESR900 and ESR 910

Cryogen transfer

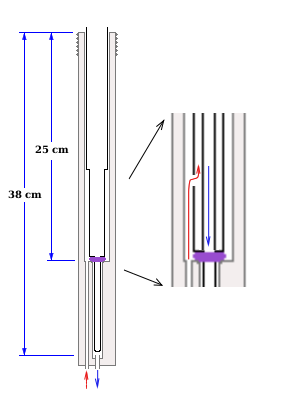

Figure shows schematic cut view of the transfer line entry port. Shape of the interior void is cylindrical with a step at 25 cm depth. Total depth is 38 cm.

Figure also shows the cryogen transfer line (TL) inserted. End of the transfer line is cylindrical with two step-wise decreases in the outer diameter. Only the thinnest part of the transfer line goes past the step of the entry port at 25 cm depth. Teflon gasket (purple) is seated at the base of the thinnest part of the transfer line. When pushed against the step inside the entry port, gasket forms the barrier between cryogen entry and exhaust lines.

Symptoms of poor cryogen transfer

If exaust of the transfer arm is frosted, but the sample is still above freezing temperature that means that cryogen is by-passing the cryostat. This most likely means that there is a leak under the gasket or the gasket is missing.

Troubleshooting

The teflon gasket and how it is centered is crucial for efficient transfer of cryogen to the cryostat. If the gasket is missing, damaged or incorrectly placed, cryogen can go directly to exhaust, bypassing the cryostat. The gasket will be off-center if the tip of transfer line is bent.

The gasket may come off the TL and get stuck inside the entry port - this can be seen by looking inside the port. The gasket can be fished out with a wire hook (~30 cm long).

It is possible that TL is not inserted deep enough if the nut securing the TL on the entry port is fixed too close the the TL end. In that case the nut can be loosened and moved a bit farther from the end of the TL.