Ice in My Dewar! (Liquid Helium Transport Dewar)

From NMR Wiki

Warning. Cryogenic Liquids and Associated Vapor are Dangerous. Wear Protective Clothing and Eye Protection.

Warning. Helium presents a great suffocation hazard. Ensure adequate ventilation when using or repairing Dewars. Never work with liquid He alone.

This is of special interest to sites which are far from their liquid helium supplier, and who perform their own liquid helium fills.

This document describes what can be done if your liquid He transport dewar exhaust line is ice-clogged.

Contents |

The Situation

The Rhodes University in Grahamstown, South Africa, is 120 km from the nearest (Port Elizabeth) Cryogen vendor’s depot. This depot does not always have a cryogenics expert available. We are 1000 km from the supply point, Johannesburg. Another Support point is Cape Town, 800 km distant. Liquid helium (and liquid nitrogen) is delivered by road transport and the transfer of cryogens to the superconducting magnets is performed by university staff members.

The Problem

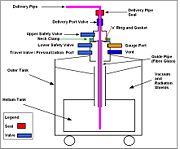

A 100 litre liquid helium delivery Dewar was found to only pressurize with difficulty and it was not possible to vent via the vent-valve (See sketch below for terminology). In additional cause for concern and alarm was the discovery that the lower safety valve did not release any gas; neither did the travel valve port . Nevertheless the upper safety valve was able to vent gas, and this was the clue to the puzzle. It was possible probe the helium tank and measure, by sounding tube, that there were close to 100 Litres of liquid helium in the Dewar.

The suggested course of action required blowing warm (room temperature or warmer) helium gas into the Dewar. He also suggested removing the delivery port / guide pipe assembly.

The Structural Details of the Dewar

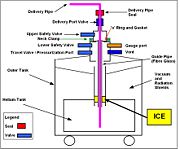

After making some measurements, and with some hind-sight after having dismantled part of the Dewar, the structure of the Dewar is believed to be similar to that shown in the figure below. This is totally the author’s idea of what goes on inside, and if any reader would like to correct this sketch the author will be delighted.

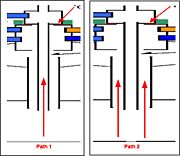

The sketch above shows the Dewar to have two regions, one insulated and containing the cryogenic liquid and the other un-insulated and containing much of the valving. Access to the liquid is via either of two paths. See the sketch below.

Path 1 passes through the delivery port and the guide pipe, while path 2, passes through any of the pressurization port, vent port, the lower safety port or the travel valve port, passing outside the guide pipe to access the helium tank. Under normal circumstances these two paths are freely connected.

To expel liquid Helium one applies ‘over pressure’ to the liquid surface by connecting pressurized helium gas to the pressurization port. In response to the over pressure liquid is forced up the delivery pipe.

Dewar Configurations

With so many valves there are a number of possible configurations. From a functional view-point there are 3.

- Travel or Storage Mode

The delivery port is closed and the pressurization port has the travel (safety) valve installed. Normal evaporation of the liquid raises the internal pressure and helium gas is vented via the travel valve.

- Passive Delivery Mode

The travel valve is removed and the port is used for pressurization by fitting a hose-connector (barb). Zero gas pressure is applied. The delivery port valve is closed and, necessarily, the delivery (or transfer) pipe is not installed. Excess pressure is released via the lower safety valve. Should path 2 be blocked, internal pressure can still be released via the upper safety valve.

- Active Delivery Mode

The delivery port valve is open. The delivery pipe is inserted into the transport Dewar. The delivery port seal is tightened. The pressurization / travel valve port valve is open and external gas pressure is applied. Liquid is forced along the delivery pipe and may now be transferred.

The Repair Procedure

Warning: Open the delivery valve before attempting to open the neck seal. This will prevent any sudden release of cold gas or liquid. Always work with a companion when maintaining cryogens: Situations develop which require extra hands or someone to call for help.

Keep the work space WELL VENTILATED while working on the dewar to avoid any risk of suffocation.

On the instructions of the vendor the neck-clamp was removed and an attempt was made to withdraw the guide pipe. It was completely stuck. Room-temperature helium gas was applied to the pressurization port at increasing pressure until the upper safety valve opened. Pressure was then rapidly reduced via the delivery port. In this way it was hoped to cause turbulence and allow some warmer helium to reach the blockage. After some minutes of this treatment there were signs of some pressurization of the helium tank but the guide pipe assembly remained stuck.

The system was allowed to rest for 2 hours and then a further attempt to move the guide pipe assembly was made. This time it slowly moved. After some minutes of struggle the assembly was removed. A cylindrical collar of Ice surrounded about 3 cm of the guide pipe, some 10 cm from its free end. Apparently the ice had sealed the access to the helium tank via path 2 as shown in Figure 2. The Ice fizzed and sublimed rapidly once in the open air. The guide-pipe/delivery port assembly was then replaced without difficulty. Thereafter the Dewar functioned normally.

Photographic Record

Below is the photographic record of the entire procedure. Click to see full size pictures.